Biomass Based Bioenergy: Technologies and Impact on Environmental Sustainability

Article information

Abstract

Biomass based bioenergy has many advantages evidently as their available quantity and renewability, when compared to the petro-derived traditional fossil fuels. Thereby, such bioenergy occupies a vital role defensively to the global energy requirement as well as guarantee energy supply. On the other hand, it should be considered that the development of biomass based energy may lead to some serious environmental issues and those are only based on the published data. Such adverse environmental alterations, mainly erosion of soil organic carbon, greenhouse gas emissions, lessening of water quantity and quality, have mainly been based on type of biomass source utilized, location of the land, and management practices. Consequently, more attention should be paid towards environmental protection, while implementing the production of biomass based bioenergy. In this study, various types of biomass, its conversion technology, advantages and disadvantages and its environmental issues of bioenergy production in terms of adverse impact on water, air and soil along with protection measures have been discussed.

1. Introduction

By the year 2030, the usage of various biomass resources would raise due to the increased demand of energy. The demand is would be possibly met by increased utilization of the waste biomass residues like starch, sugar, and oil crops, progressively more from lignocellulosic crops, which is based on the picking of crop and planting rates, environmental and logistical constraints, and availability of water resources [1]. The demand or necessities of global energy level increases hurriedly, due to rapid growth and developmental activities of modern industrialization, transportation and domestic activities. Hence, many researchers are working to upgrade novel energy resources alternative to fossil fuels [2]. Furthermore, these resources are derived from inexpensive and easily or nearby available non-food materials. Every year, about 100 billion metric tons (BMTs) of biomass wastes are produced from various agricultural, forestry and industrial resources and these biomass materials could be utilized as promising bioenergy sectors worldwide [3]. The production of biomass wastes (in Mt: million tons), originated from various agricultural sources are rice straw (731 Mt), wheat straw (354 Mt), corn straw (204 Mt), sugarcane bagasse (181 Mt) and rice husk (110 Mt) as well as around 73 Mt of forestry residues (during harvesting and product processing) [4,6]. Traditionally, the biomass and its residues have been widely utilized as significant bioenergy and bioproduct producing resources, around 10~14% of the global energy demands have been fulfilled from biomass supplie [7,8]. Approximately 25% of biomass bioenergy are widely utilized in industries for power generations and remaining 75% is used for household heat generation (cooking and firing) activities. During the photosynthesis process, the green plants (chlorophyll) react with water (in the atmosphere) to produce electrons (e–) and protons (H+) and use them to turn CO2 (in the atmosphere) in the presence of solar radiant energy (as a catalyst) into energy rich chemical products (glucose or carbohydrate) and release O2 (as a waste product) as:

Though, the energy producing biomasses have been widely utilized in major of the bioenergy production sectors, an alternative to conventional fossil fuel energy resourced demands behind the coal, crude oil or petroleum and natural gases [8-12], there are certain impacts of biomass based bioenergy production on the water quantity and quality, followed by GHG (greenhouse gas) emissions, and erosion of soil organic carbon (SOC). Furthermore, the publications related to energy producing biomasses and their impacts on our environment imply that some awareness should be given towards protection of the environment while supporting the expansion of biomass based bioenergy developement [13]. This review focuses on various types of biomass resources, biomass conversion technologies, advantages and disadvantages of biomass materials and the environmental impact of bioenergy production on water, air and soil and protection measurement.

2. Types of Biomass resources

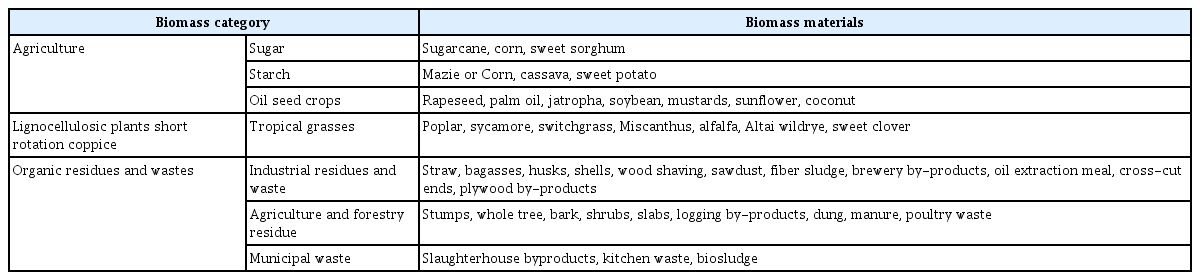

Generally, biomass sources are organic matter and containing C, H and N / O / S, derived from any type of plants as well as animal species of the biosphere. According to the IEA (International Energy Agency), the biomass and its materials are derived from biogenic sources, mainly animals and plants from wood and agricultural crops, and organic wastes from municipal and agro-industry [14]. The classification of biomass materials has been approached, based on some important facts like their life cycle, origin, fibrous nature, aquatic/terrestrial nature and yield. Based on the origin, the biomass sources are further classified into three types as are illustrated in Table 1 [15]:

· Organic residues and wastes: include agriculture and forestry residue (e.g. Trees, wood, wood waste, dung, manure, poultry waste), municipal waste (e.g. Food waste, yard clippings, refuse derived fuel, kitchen waste, biosludge) and industrial residues (e.g. Sawdust, timber slash, mill scrap, brewery by-products, oil extraction meal) [11,15-20].

· Lignocellulosic residues: such as switchgrass, miscanthus, alfalfa, Altai wildrye [15].

· Product from agriculture: such as palm oil, jatropha, soybean, mustards, sunflower, coconut [15].

Biomass material resources can be categorized as traditional and new (modern) biomasses, based on the energy sector utilization. Traditional biomasses are used as non-commercial sources (e.g. Food cooking), whereas the new biomasses (e.g. Methane and ethanol generation from biomass) [16,21] are effeicient commercial sources. Moreover, the increasing utilization of biomass source as a promising future bioenergy sector could act as the chief emerging alternative resources to fossil fuel, to reduce the GHGs emission and also foster bioeconomy. During the thermochemical (combustion, co-firing, gasification, hydrothermal liquefaction, pyrolysis) and biological (anaerobic digestion, alcohol fermentation) conversion processes the biomass materials containing, high percentage of O and low percentage of C and H contents have been converted to different form of sustainable energies in he form of solid (biochar) or liquid (bio-oil or biofuel, bioethanol, biodiesel) or gaseous (bio-H2, bio-CH4, bio-syngas) fuels, electric power, heat energy and useful cost-effective high value added bioproducts towards biochemical, biochip, biofertilizer, biopolymer industries [8,22,23].

3. Biomass Conversion to biofuels

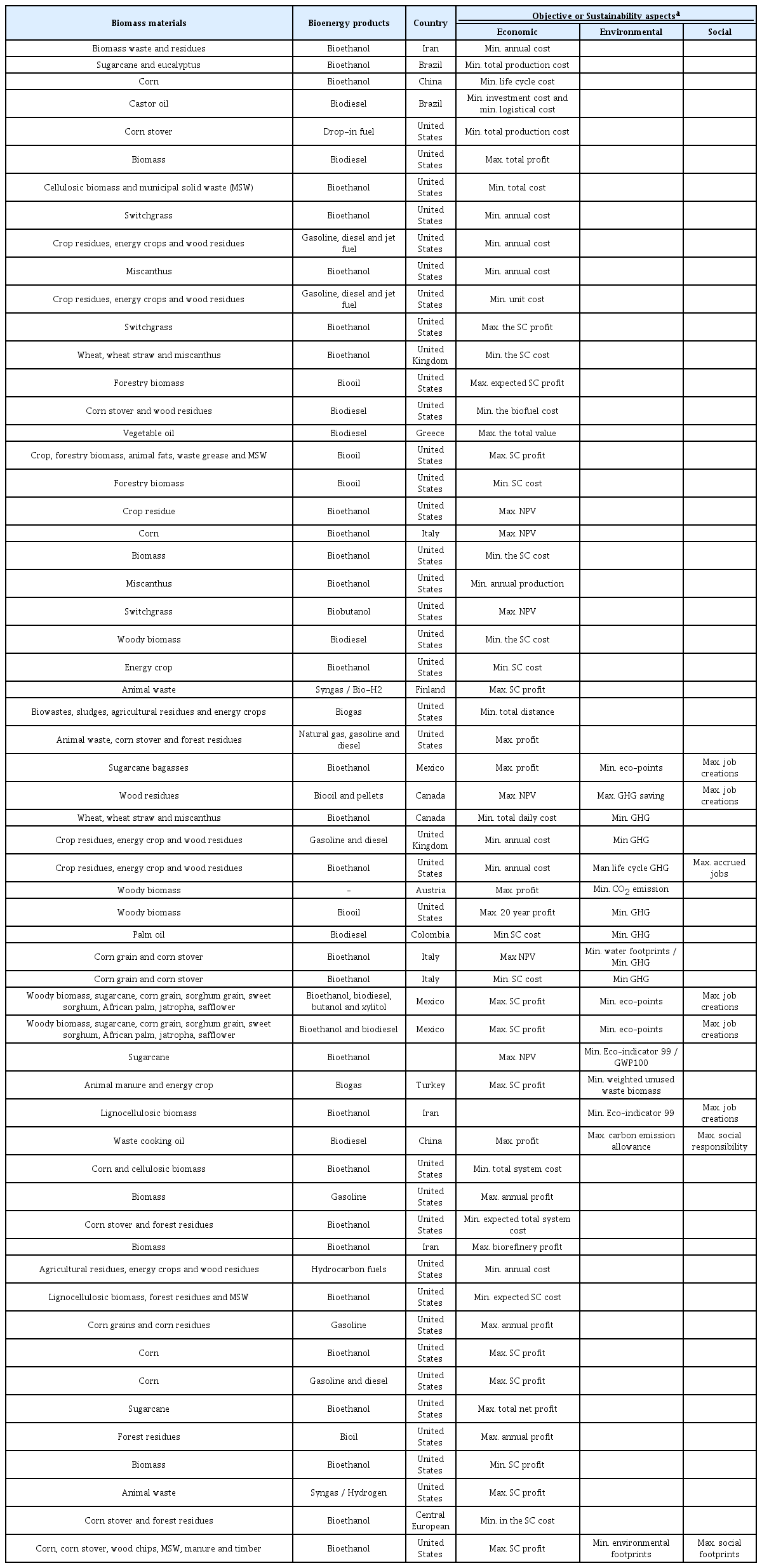

The production of bioenergy and biofuels from various biomass materials have been classified, according to the type of biomass materials and their residues utilized [15,20,24,25]. Fuels generated through biomass are classified as first, second, third, fourth generation biofuels.

3.1. First generation (1G) biofuels

First generation (1G) biofuels are generated from different types of food crops (rice, wheat, rapeseed, sorghum, sugarcane, corn). Biodiesel and bioethanol are the primary first generation (1G) biofuels [17]. In 2015, the USA (14.81 billion gallons) and Brazil (7.09 billion gallons) produced around 85% of the global bioethanol [15]. The USA uses corn biomass as a primary source for bioethanol generation, whereas Brazil uses mainly sugar cane [15,17]. In the Europe Union sugar beet and starch crops represent the primary sources of bioethanol production (around 3.44 billion liters) [17].

Biodiesel has been generated from oilseed crops (palm oil, soybean, sunflower, canola) [15,17]. In 2006, the world’s biodiesel generation was reached more than 6 billion liters. The largest biodiesel producer is Germany with 2.5 billion liters, primarily derived from sunflower and rapessed. The second largest producer is the USA, which produces 0.86 billion liters, overall the biodiesel generation has been increased in some countries (France, Austria, Italy) [17].

However, primary biomasses for the first generation biofuels pose a significant issue while the production of biofuels depends on the food crops supplies and their cost.

3.2. Second generation (2G) biofuels

The second generation (2G) biofuels are generated from lignocellulosic biomass (containing 30~50% of cellulose, 15~35% of hemicellulose and 10~20% of lignin) and their residues, derived from the agriculture (straw, corn stover, sugar bagasse, vegetative grasses, wood along with their wastes, energy crops and their residues), forest residues. The production of second generation biofuels from lignocellulosic biomass solves the problem of food competitiveness related to the use mainly of sugar cane and corn as feedstocks for the production of first generation biofuels [15,17].

3.3. Third generation (3G) biofuels

The engineered algae are a rich energy source and is widely utilized for third generation biofuels production either directly or through some conversion process. In addition, algal species have high sugar or lipid or oil contents with a high growth rate as well as it is easily cultivated in lagoons or open ponds, under specific conditions and not at all influence the food production in the land areas [24]. Hence, the production of bioenergy from the algal feedstock is considered as a future energy source and potentially replaces fossil fuel demands.

3.4. Fourth generation (4G) biofuels

Fourth generation biofuels increase the production of biofuels, using some metabolically engineered species (engineered algae, bacteria, some other microbes), combining CO2 capture and energy storage capability. During the production of biofuels, some of the species have high percentage of lipid content, which can be further degraded into high value added bioproducts like polymeric hydrocarbons or petroleum products [24,25].

4. Biomass conversion technologies

During the conversion technologies, the biomass materials or residues are converted into specific bioenergy with high value added bioproducts. Several types of biomass conversion technologies (BCT) have been employed for obtaining bioenergy and bioproducts [17,25-28]. The advantages and disadvantages of the conversion technologies are summarized in Table 2 [25,28].

4.1. Thermochemical conversion:

Heating coupled chemical processes are mainly utilized to produce bioenergy from biomass materials. During the thermochemical conversion, the biomass material is treated at high temperature to produce solid (biochar), liquid (high oxygenated bio-oil), and gaseous (syngas) form of bioenergies. The main thermochemical conversion methods are gasification and pyrolysis. In gasification technology, the biomass is converted to syngas containing CO2, CO, H2 and CH4. The gasification process is performed at very high temperature (over 600℃) with lower oxygen content in a gasifier reactor [29]. Syngas are used as stationary biofuels or for ethanol, diesel and ethanol through Fischer-Tropsch conversion [15,25]. Pyrolysis process provides the biomass conversion at an average temperature of about 300~600℃ and in the absence of oxygen to liquid (bio-oil), solid (shar) and gas. The proportions of such products are depending on the feedstock type, heating level and residence time [30].

4.2. Thermal conversion

During thermal process heat (exothermic) energy is utilized for converting biomass into bioenergy, this technology and include direct combustion, co-firing, pyrolysis and torrefaction. Industrially, several types of biomass materials like wood, agricultural residues, wood pulping liquor, MSW, can be burnt or combusted directly to produce heat and generation of electric power (renewable energy source). However, this method it’s not effectively utilized, due to high percentage of ash formation during combustion of most of the biomass materials.

4.3. Biochemical conversion

Enzymes, bacteria or other microbes are used for converting biomass into biofuels, it includes anaerobic digestion and alcohol fermentation. During the fermentation process, the microorganisms interact with sugar based (sugarcane, sweet sorghum) as well as starch based (corn grain) biomasses into recoverable bioproducts (bioethanol). The obtained bioethanol is further used for the production of biopolymers (polyethylene) or blended with gasoline (E15) [25,31]. Anaerobic digestion (AD) process consists the breakdown of biodegradable biomass into biogas by microorganisms at a temperature, ranging between 30 and 65℃, but there is no air [17,32-34], these biogas cam be considered as an alternative to natural gas.

4.4. Microbial electrochemical technologies (METs)

Currently, the main global agenda issues are the energy and freshwater [35]. Waste and wastewater treatment can be an important resource for bioenergy production and environmental pollution removal [36]. Several wastewater technologies are used to provide the energy requirement, such as anaerobic digestion and heat pumps [35]. Newly, microbial electrochemical technologies (METs) have been developed for the energy extraction and producing valuable chemicals from wastewater, using electrically active bacteria (EAB) [37]. METs process provides significant advantages, including power recovery in various forms and less sludge production over the conventional biological treatment technologies [35]. The METs process can be classified to: microbial fuel cell (MFC), microbial desalination cells (MDC) and microbial electrolysis cell (MEC).

4.4.1. Microbial fuel cell (MFC)

The microbial fuel cell (MFC) process allows the transformation of organic matter to bioelectricity through electrochemically active bacteria (EAB) [38]. EAB oxidizes organic matter, causing release of electrons. The MFC includes an anode chamber, a cathode chamber which are separated by an ion exchange membrane (IEM) [39]. In MFC, the releasing electrons and protons are resulting from the organic matter oxidation by EAB at the anode chamber which are passed to the cathode by the external circuit and the IEM, respectively [36,37]. The flow of electrons leads to electricity production [36].

4.4.2. Microbial desalination cell (MDC)

Microbial desalination cell (MDC) is suitable for bioelectric energy generation from the wastewater and simultaneously desalinating seawater [35]. The MDC can be constructed, when an extra chamber is added between the anode and cathode chamber in the MFC [40]. MDC includes an anode chamber, a cathode chamber, an anion exchange membrane (AEM) and cation exchange membrane (CEM) [40]. In MDC, EAB oxidizes organic matter to electrons and protons at the anode [35]. The free electrons are subsequently passed to the cathode by the external circuit [35,40]. The anions (Cl–) can be transported to the anode through the AEM and simultaneously the cations (Na+) get transported to the cathode through the CEM, concurrently with the electros transfers [41]. This system allows a simultaneous electricity generation and water desalination without additional any energy sources [35].

4.4.3. Microbial electrolysis cell (MEC)

The microbial electrolysis cell (MEC) provides biohydrogen generation and wastewater treatment [40]. The MEC process configuration are similar to that of MFC, the difference is an external voltage is applied and the cathode are maintained in anaerobic environment [40]. In a MEC, the BAEs present in the anode oxidizes the organic matter to electrons, the released electrons are transferred to the cathode via a separator and are reduced to biohydrogen [41]. Recently, MECs have gained attention extensively among the researchers that obviously represents nearly about 75% publication in this field [42,47].

5. Advantages and disadvantages of biomass materials

With a rapid increase in the productions of biomass based bioenergy and bioproducts as they possess numerous advantages (i) biomass is a direct source of clean energy, (ii) it is an ultimate as well as continual alternative to fossil fuel resources, (iii) the source materials are easily and available in huge amounts and cheaper than fossil fuel materials, (iv) the integrated biorefineries of industrial wastes as well as other feedstocks produce high added value biochemicals, biofuels and biopolymers, (v) low content of S and N (i.e., less emission of SOx and NOx to the environment), (vi) significant calorific values as compared to fossil fuels, (v) does not increase the CO2 emission in the biosphere, it also acts as a carbon-neutral or green house neutral energy resources, i.e., burning or combustion of any biomass material releases carbon (as CO2 or greenhouse gas) to the environment and then CO2 is absorbed for their growth of all the greenish plants (biomass) during their life cycle, as a result, the net balance amount of CO2 emission and its absorption to the atmosphere is maintained as zero or neutral throughout the usage cycle of biomass, (vi) reduces the quantity of waste in landfills [45,47]. However, discharge of immense amount of CO2 gas along with particulates by direct burning of biomass materials have some negative impact of human health and the environment [48,49].

Hence, some of the challenges towards the utilization of biomass material resources and considerations about CO2 emission can be recapitulated as,

· Shortage of clean and green traditional biomasses and land availability for energy producing purposes,

· Identification of novel biomass sources,

· Optimization in the production of bioenergy or biofuel techniques with requirement of minimum energy, maximum transportability, and compliance with handling equipment in power plants.

· The developed bioprocesses permit extraction of numerous phosphorous like nutrients the developed bioprocesses permit extraction of numerous nutrients

· Development on various combinations in conversion or biorefinery processes,

· results in the need to extract numerous high added value byproducts.

6. Impact of Bioenergy Production on the Environment

The impact of biomass bioenergy on the environment has gradually been increased, the term “water quantity and quality” occupied first place (16%), consequently by emissions of GHGs (6%), followed by SOC (5%), in the year of 2017.

6.1. Impact on water

Hoekman et al. [50] and Zhou et al. [51] illustrated that consumption of water by corn biomass and utilization and conversion of the land, mostly from its native form to perennial grasslands like miscanthus and switchgrass. This consumption also considerably and directly affects the hydrological processes, namely ET (evapotranspiration), quantity of water content in soil, surface runoff, total water content, and at a regional scale for the production of the first–generation ethanol biofuel (100 million gal/year). They found consequently that stress in water scales as that crop needs more water during its cultivation when compared to other crops like wheat and soybean, particularly in its joining stage that varies with watershed and harvest rate [52]. Guo et al. [53] proposed that such land transition for energy producing crops, at the watershed scale may cause diminution of water resources. Similarly, in the case of water quality there is a big concern towards nutrients pollution, mainly by nitrate that may be caused by surface runoff and infiltration to groundwater [54]. It may be reduced by following rotational cultivation of corn and soybean [55] and cultivating perennial grasses, which all can effectively reduce nearly 30 ~ 40% of the total nitrogen [53,56]. Qin et al. [57] suggested that it is possible to reduce and balance such issues by selecting and cultivating proper crop species with optimal management like appropriate fertilization, irrigation, and rate of harvesting.

6.2. Impact on air

The land transition to bioenergy feedstock production mainly impacts on the main components of the GHGs such as CO2 and N2O. 58) Harris et al. [59] suggested that the conversion of arable land for cultivating second generation bioenergy crops could lead to a small diminution of CO2 emission to the atmosphere, while native grassland land transition to cultivating the first generation bioenergy crops and short rotation coppice (SRC) demonstrates an increase in emission of CO2. Consequently, some considerations should be given to select appropriate bioenergy crops along with keen management practices to mitigate the emission of CO2. Similarly, Harris et al. [59] also revealed that conversion of the arable land to SRC as well as perennial grasses could reduce the emission N2O also (–0.2 t/ha year). While, the transition of the grassland to SRC, nitrogen manure application and ethanol biofuel production could make a slight increase in N2O emission. Thereby, they concluded that selection of land location can minimize and control the N2O emissions considerably.

6.3. Impact on soil

The quality of the soil has been determined by soil organic carbon (SOC), which is the significant soil index. The SOC only benefits water retention, soil biodiversity, and crop productivity of the soil. While producing biomass based bioenergy, three facts viz. removal of residues, tillage practices, and utilization of land strongly influences the SOC via soil disturbance. Hoekman et al. [50] predicted that there is a direct stimulation in loss of SOC during, harvesting of dead plant residues i.e., removal of residues. It is attributed to an abnormally reduced carbon input, which can be controlled by optimization in removal of residues, addition of nutrient rich fertilizers and biochar [60]. Overall, Li et al. [61] and Pourhashem et al. [62] predicted that such practices not only accumulate the SOC but also the elemental carbons in the form of CO2 of the air, which is due to electronegativity of the organic aggregate. Management of tillage practices for SOC can be simulated using a biogeochemical model, proposed by Drewniak et al. [63] McCalmont et al. [64] have done SOC sequestration to minimize the loss, at the time of transition of arable land to perennial grasses. They emphasized that arable land utilization for Miscanthus can accumulate organic carbons with a sequestration rate of about 0.42~3.8 Mg C/ha year. Further, mitigation of NOx and CH4 could nourish not only the soil carbon sink but also the air quality protection [62].

5. Conclusion

It is to be expected that there might be substantial growth in the production of biomass based energy over the next 20 years. It has been observed that there is a potential tremendous increase towards such production. For instance, by the year 2030 it is estimated that biomass based energy from the waste residues and energy crops in EU may range from 4.4 to 24 EJ. The biomass based bioenergy is an alternative to fossil fuels and provides an essential contributor to the global energy security due to their availability and renewability. This review summarizes various types of biomass, its conversion technology, advantages and disadvantages and environmental impacts of bioenergy production on water, air and soil along with protection measures. Based on the published reports, it is advisable to provide great attention to issues on quantity and quality of water amongst the other influencing terms while producing biomass based bioenergy. Emissions of GHGs and SOC are the other two adverse effects on the environment, which all mainly depend on types of biomass, land sources and optimal management practices. Hence, predicting the apparent areas for cultivation, a suitable type of crops, and management practices, we can favor both the production of biomass based bioenergy and our environment.

Notes

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.